Why Precision Matters

Sheet metal bending is one of the most critical operations in fabrication.

Even a deviation of 1–2 degrees can cause:

- Misalignment during assembly

- Gaps or interference between mating parts

- Increased stress on fasteners and welds

- Rework, scrap, and production delays

At Mhatre Hitech, we treat bending not as a simple forming step, but as a precision engineering process.

What Affects Bending Accuracy?

Several factors influence the final bend angle and dimensions:

- Material type and thickness – different steels and alloys spring back differently.

- Tooling quality – worn punches and dies lead to inconsistent results.

- Machine calibration – poorly maintained press brakes cause angle variations.

- Operator skill – experience matters when handling complex components.

How Mhatre Hitech Ensures Precision

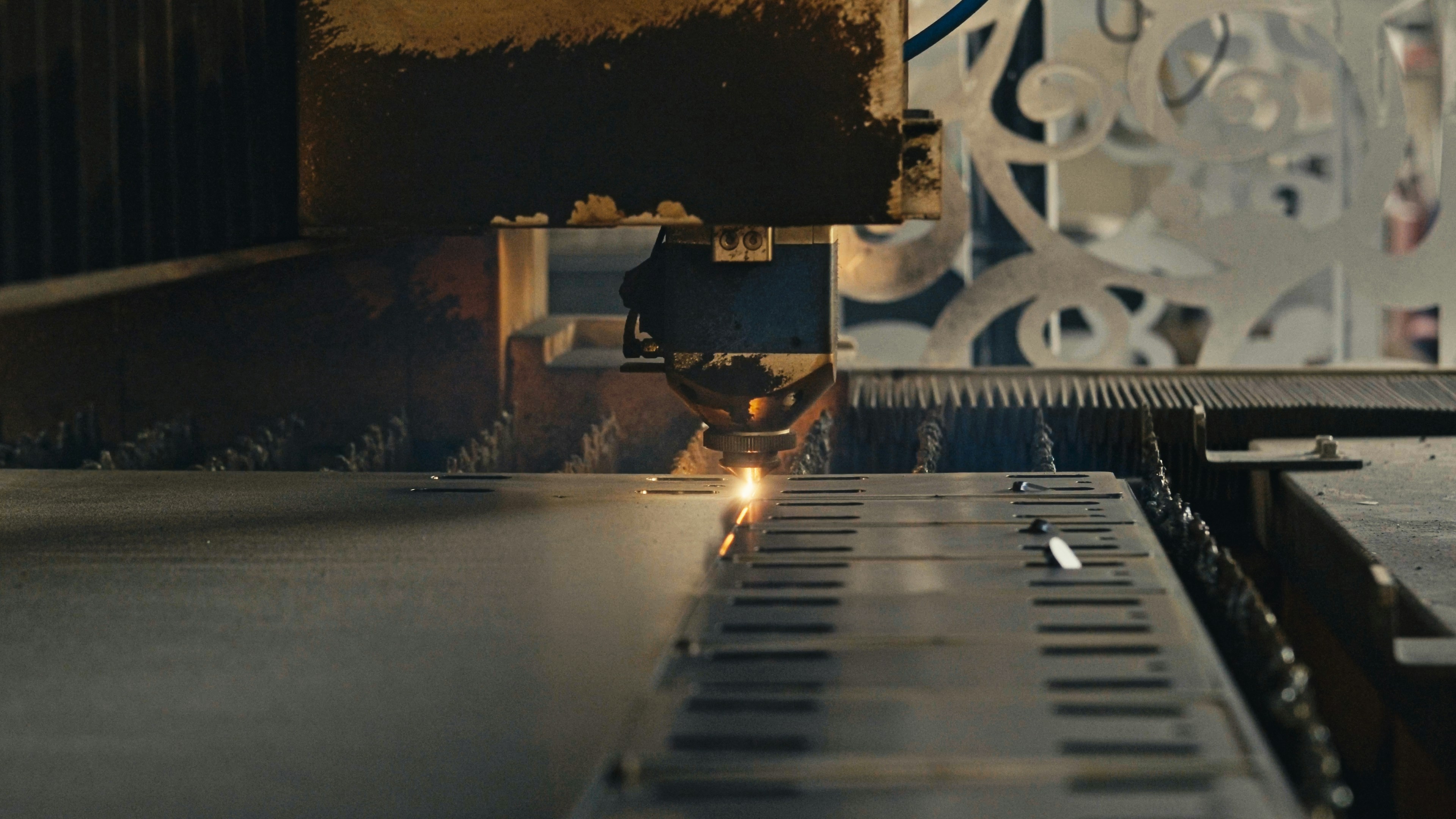

We use CNC-controlled press brakes with digital angle control and offline programming. Our process includes:

- Material batch verification

- First-piece inspection and approval

- In-process checks at defined intervals

- Final dimensional inspection before dispatch

This approach ensures your panels, brackets, cabinets, and frames assemble perfectly on your line—every time.

Where Precision Bending is Critical

- Electrical enclosures and control panels

- Automotive brackets and structural parts

- Machine guards and safety components

- HVAC ducts and architectural metalwork

If your project demands tight tolerances and repeatability, our bending capabilities are designed for you.